Just because something is relatively common in practice, doesn’t mean it’s always correct. In fact, we’re seeing surge protection installations that aren’t just incorrect–they also go against the National Electrical Code (NEC) and can ultimately result in an electrical safety hazard. What’s the main issue? “Double tap” installations of line side Type 1 surge protective devices.

We aren’t going to bury the lede on this one, so here’s a key takeaway for installers and integrators: a Type 1 surge protective device (SPD) doesn’t need to be installed on the line side of the main breaker, so avoid the issue entirely with an installation on the load side. If this suggestion seems surprising at all, you may have been “double tapping,” or you just want to be more informed about your installations. Either way, let’s break it down.

For starters, UL1449 5th Edition states that Type 1 SPDs are listed for installation on the line side or load side of the service equipment overcurrent device and are intended to be installed without an additional overcurrent device. Yes, exactly – that does mean that Type 1 SPDs can be installed as a Type 2 device (but it’s important to note that UL listed Type 2 devices cannot be installed on the line side).

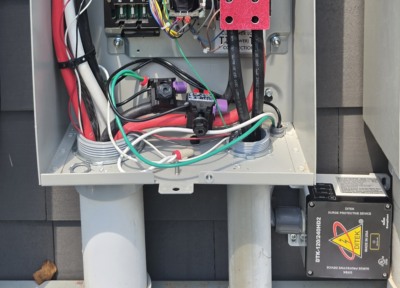

When it comes to safely completing the installation of an SPD on the line side of a main circuit breaker, the electric meter needs to be disconnected. However, in many jurisdictions, the utility company prohibits this and may have a safety seal implemented to prevent it entirely. This can greatly increase the installation time if the utility company has to be called out to disconnect the meter. Therefore, it is much more practical to install the SPD on the load side by adding a dedicated circuit breaker, terminating via a “pig tail” off an existing circuit breaker, or by utilizing an existing circuit breaker that is UL listed for multiple conductors.

Now, you may have seen installations where the SPD was double tapped under the main breaker lugs. How is this happening? In many cases, it was missed during an inspection. It’s also possible that the contractor has been installing them that way for years and didn’t know any better. In other cases, crimp-on flat blade terminal connectors (sometimes provided with the product by an SPD manufacturer) may have been crimped onto the SPD wire leads and then landed under the same lug as the service entrance conductors. This method is still considered “double tapping.” The flat blade terminal connectors are not UL listed for the purpose of double tapping a lug that is not rated for multiple conductors. In order for this to be done correctly and code-compliant, the lug would have to be explicitly listed for multiple conductors as referenced in NEC 110.14(A). Even in the unlikely scenario that the main circuit breaker is rated for multiple conductors, the conductors would also need to be identical in wire gauge and type.

Using crimp-on blade terminal connectors also presents another issue, especially regarding residential applications–these types of terminal connectors are typically manufactured using tinned copper while many residential installations use aluminum SER (service entrance) cables for connection to the main electrical panel. Mixing tinned copper connectors with aluminum conductors under the same electrical termination creates a dissimilar metals situation where galvanic corrosion can occur. This, of course, can be an electrical safety hazard.

The bigger issue–even if manufacturers’ documents show this as an acceptable method of installation–is that it’s still not compliant with the code nor safe. And a manufacturer’s instructions shouldn’t override safety and inspections. In fact, more and more inspectors are closely looking at these installs to ensure they’re up-to-code.

So, now what? If you do still prefer to install the SPD on the line side of the main breaker, and you’re located in a jurisdiction that allows the electric meter to be disconnected by the licensed electrical contractor, you must use a UL listed termination method that does not violate the NEC “double tap” rule. While UL does say a Type 1 SPD can be installed on the line side, it does not say to “double tap” the main breaker.

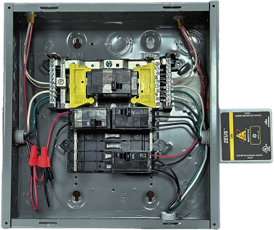

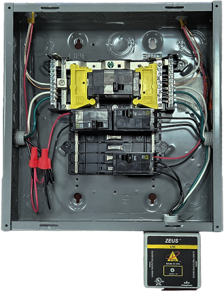

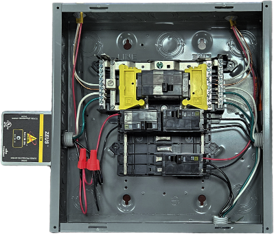

All installations should ultimately adhere to applicable national and local electrical codes, and there are compliant methods to use. Acceptable termination methods that do not violate the NEC “double tap” rule include:

- Piercing tap (also called “vampire taps”)

- Multi-tap connectors

- Multi-tap lug adapters

The importance of adhering to the NEC and UL-listed methods cannot be overstated. Not only does it ensure the safety of the installation, but it also maintains the integrity of the electrical system. By avoiding this common pitfall and choosing a compliant solution, installers can ensure that their practices are both effective and safe, ultimately protecting the homes and businesses that depend on their expertise.

Approved installation methods can look like these:

Explore more installation best practices at DITEKUniversity.com!

View our Product Installation Guides here for your surge protection installations.